ETCO Inc. Releases Manufacturing Guide on Product Considerations for Progressive Die Manufacture

Bradenton, Florida (PRWEB) April 19, 2012

Bradenton, Florida (PRWEB) April 19, 2012

ETCO Incorporated, an American manufacturer of custom precision stampings, automotive ignition components and medical equipment announced the release of its Product Consideration Guide for Progressive Die Manufacture today. The guide was published on ETCO’s website with information to help manufacturers shorten lead times and produce higher quality components within end products.

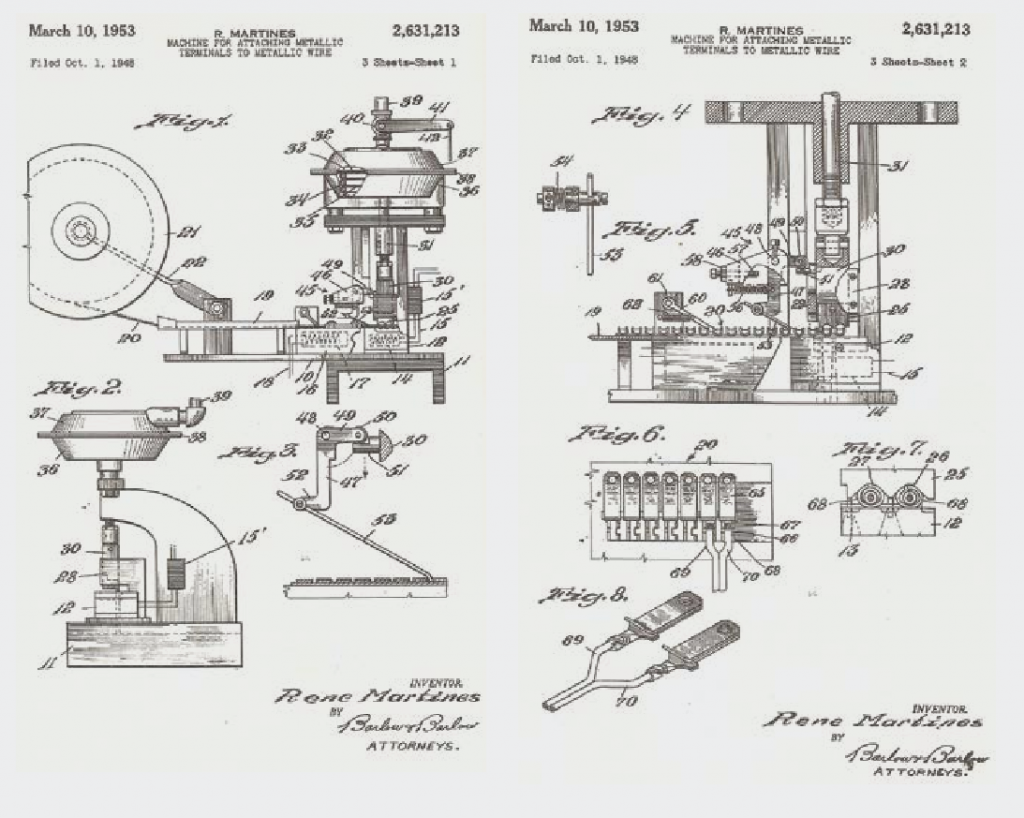

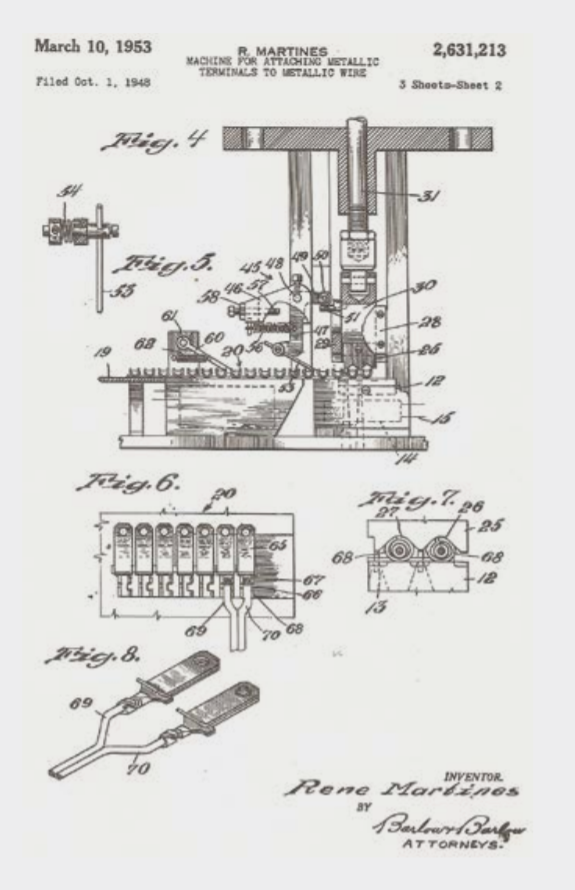

Recognizing issues related to time constraints and efficiency when manufacturing complex parts, the engineers at ETCO prepared an eight-page guide that details the processes involved with progressive stamping. From bending to coining to punching, ETCO’s guide explains best practices for lowering production costs. The engineers walk through in text the general tolerances and standard design practices with step-by-step diagrams and explanations. Additionally, the guide covers general tolerances, standard process capabilities and a nearly exhaustive general notation section for reference.

In addressing the advantages of having a guide of this nature, Director of Engineering at ETCO, Mike Cummings states that, “this guide is important for manufacturers in general because it gives a view on using the most efficient methods for development when working with ETCO. The cost savings alone when looking at how we lay out exact tolerances and specifications is a big help for our manufacturing partners.” The release of the guide also coincides with ETCO’s push into the medical equipment and device industry, as illustrated on the ETCO website.

While ETCO has released white papers in the past specifically related to automotive parts manufacturing, this guide is the first of its kind from the company. It allows manufacturers to get a handle on costs they control within the manufacturing process. It also enables manufacturers who are new to working with ETCO a view on efficient progressive die development.

Founded in 1947, ETCO is a privately owned company. The Company manufactures precision stampings and rubber and plastic molded products used principally by major automotive and appliance manufacturers. ETCO also has major customers in a variety of other industries in the USA and over 30 countries throughout the world.

ETCO has factories and a research complex in Bradenton, Florida and a factory and engineering center in Warwick, Rhode Island.

For more information on ETCO, visit the Company website online at https://www.etco.com