When locking ring terminals don’t really lock it squanders time on the production floor, especially if the screw needs to be removed and re-fastened, potentially damaging the harness. There also is the possibility of arcing or electrical shorts with adjacent terminals at some point down the road. A secure connection is absolutely critical to production efficiency and the integrity of the circuit.

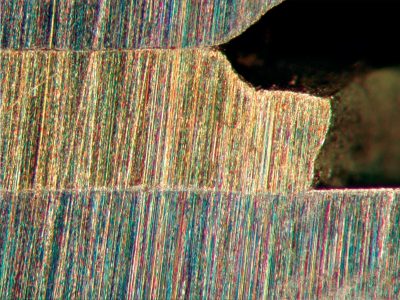

The teeth on ETCO’s locking rings extend .023” inches from the terminal surface. The teeth are a full 92% of the thickness of the ring itself and the 40-degree angle of the teeth provides sharp steel wedges that give the terminal its superior bite. These features allow penetration into metal surfaces, painted or not.

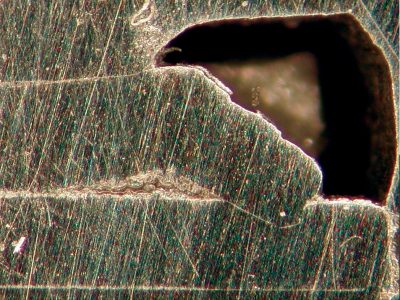

If you look at the competition’s terminals they are typically made of brass with simple tang folds extending just .012″. It is easy to understand why ETCO’s locking rings are superior and much more likely to provide a more secure connection and improved output on the production floor.

ETCO had become aware of problems in the field where locking ring terminals on ground wire attachments of appliances have loosened. ETCO’s research team set out to analyze and test locking ring terminals used for ground connections on appliances. The project’s hope was to offer a terminal having improved performance characteristics on applications where ground terminals are attached to appliances’ steel framing.

Terminals were measured, photographed and subjected to different test procedures including, tensile/crimp retention to wire, crimp cross sections, terminal torque retention to surface measurements, cross sections of terminal’s surface penetration, corrosion/salt fog chamber exposure, and electrical testing.

ETCO’s steel teeth are .023” and hold their shape.

The competitor’s teeth are .012” and compress under pressure.