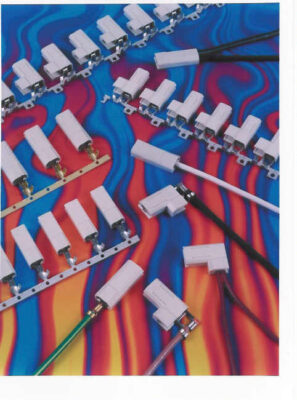

Custom Electrical Terminals Engineered to Meet OEM Requirements

Custom engineered and manufactured electrical terminals that can be integrated into a wide range of automation systems to meet specific OEM requirements are available from ETCO Incorporated of Warwick, Rhode Island.

ETCO Custom Electrical Terminals can be manufactured from a wide range of clad and inlaid alloys in a variety of configurations from 0.008″ to 0.090″ thick with tolerances to ±0.002″, depending upon the materials and design. Engineered to meet OEM requirements, they can be integrated into a wide range of automation systems, such as robotic handlers, automated assembly systems, vision inspection systems, and pick-and-place machinery. Developed using rapid proto-typing with 3-D solid modeling and analysis, ETCO Custom Electrical Terminals are typically suited for production capa-bilities from 500,000 parts/yr. Supplied on reels, these custom terminals are produced using precision, progressive stamping and forming, with in-line degreasing, parts washing, labeling, plating and packaging, as needed.

ETCO Custom Electrical Terminals can be manufactured from a wide range of clad and inlaid alloys in a variety of configurations from 0.008″ to 0.090″ thick with tolerances to ±0.002″, depending upon the materials and design. Engineered to meet OEM requirements, they can be integrated into a wide range of automation systems, such as robotic handlers, automated assembly systems, vision inspection systems, and pick-and-place machinery. Developed using rapid proto-typing with 3-D solid modeling and analysis, ETCO Custom Electrical Terminals are typically suited for production capa-bilities from 500,000 parts/yr. Supplied on reels, these custom terminals are produced using precision, progressive stamping and forming, with in-line degreasing, parts washing, labeling, plating and packaging, as needed.

ETCO Custom Electrical Terminals are priced according to design and quan-tity. The firm provides EDI order processing, is ISO 9002 and QS 9000 qualified, and uses Philip Crosby quality management methodologies.